|

Water boreholes in and around Bourne Water during the 19th century was extracted through a number of boreholes drilled at strategic points around the town to take advantage of the underground sources. Among the first to be sunk was a borehole for the newly-formed Bourne Waterworks Company in 1856 on land now occupied by a bungalow at No 39A North Road.

Until recent years, this property had a raised front garden and the sealed bore stood within the brick chamber below, although now demolished. This was the original 19th century source for the supply of Pure Bourne Water marketed by R M Mills & Company.

Two years later one of the most productive bores was discovered in Bourne and the Grantham Journal reported on Saturday 28th August 1858:

An extraordinary spring has been found on land belonging to J Lely Ostler Esq which now supplies the waterworks at Bourne. After boring some distance through different strata of earth, this remarkable spring was found, and it has been affirmed by the engineer that there is only one other of the kind equal to it in Europe, and that is in Paris. It will, by its own natural force, throw the water 25 feet above the earth's surface and moreover it will emit no less than 365 gallons per minute, and in one hour will supply Bourne with sufficient water for a day and night, allowing each person to consume ten gallons. It is asserted that it is capable of supplying Spalding and Boston and it has been contemplated that in the course of time it may be carried to Spalding. It will be seen that in twelve months it would supply the enormous quantity of 191,844,000 gallons, which would allow each person in each of the above named places to consume in one year 6,381 gallons, or about 17½ gallons a day for each individual.

There were others on the site of the new market place in front of the Corn Exchange and in Manning Road on land now occupied by Johnson Brothers agricultural machinery depot but not all produced a wholesome water supply. The pinfold bore, for instance, was sunk in 1880 by the Bourne Waterworks Company behind the Marquis of Granby public house in Abbey Road but its water had a high contamination of iron and rotting vegetation, causing problems for householders and breweries who used it.

During a court hearing at Lincoln Assizes on Saturday 18th February 1888, the Bourne Waterworks Company was sued by the brewers, Joseph Wyles and Company, for providing water that was not fit for brewing and it was alleged during the hearing that this water came from the pinfold bore. Mr Frederick Vinter, Sanitary Inspector for the Bourne Rural Sanitary Authority, said in evidence that the pinfold bore was connected with the main in Star Lane and it would flow with other water down Eastgate. Shortly afterwards, he had complaints from that part of the town as to the water and in 1884 he called this to the attention of the directors, the water having an offensive smell. In June 1887, he saw men at work cutting off the supply from the pinfold bore and it had not been used since.

Several other boreholes were sunk at various places around Bourne, particularly in those areas where users were having difficulties and some of these were sunk by private individuals. In August 1887, following complaints about the inadequacy of the supply, a boring was made in the yard at the rear of the Bull Hotel (now the Burghley Arms), reaching a depth of 93ft 2in and subsequently producing water at the rate of 170 gallons a minute. The operation was carried out by Messrs Thomas Nowell at a cost of £30. In September that year, a borehole was also drilled on Mr Henry Goodyear's property in the Austerby where it reached a depth of 104ft., despite some technical difficulties with the equipment caused when it reached a layer of solid rock.

The borehole sunk by the Bourne Waterworks Company in West Street, near Manor Lane, in February 1888 was the most important so far in the history of the town because, as the Stamford Mercury reported on Friday 2nd March:

The inhabitants of Bourne have now the benefit of a plentiful supply of good water, the bore producing 280,000 gallons of water of excellent quality daily. 150 yards of new piping for the purpose of connecting with the main drain have been laid down by Mr Hinson and the water is now in full supply.

A similar report appeared in the Grantham Journal on Saturday 3rd March:

THE NEW WATER BORE: A good supply of water was found at a depth of nine-nine feet from the new bore in Dr [James Watson] Burdwood's paddock. The bore produces a supply of 280,000 gallons of water per day, of excellent quality. The contact has been carried out on behalf of the Bourne Waterworks Company by Messrs Isler and Company. One hundred and fifty yards of new piping, connecting the bore with the main, have been laid down by Mr Hinson, and the public have now obtained the benefit of a plentiful supply of water.

An attempt had been made on the same site some years before but the work was abandoned when equipment was damaged. A chisel 2 ft. 9in. in length become so firmly embedded in the rock that all attempts to remove it were ineffectual. Mr Gribble, manager for the contractors, Messrs C Isler and Company, eventually used a clamp to bring the chisel to the surface from a depth of 94 feet and then announced his intention of boring through the rock because he thought that a copious supply of excellent quality water could be obtained from the spring between the rock and a lower layer of limestone and in the event, his opinion proved to be correct. There were fewer difficulties this time and the operation was made easier through the use of an improved system of artesian tubing, thus avoiding the danger of contamination by foul air and other impurities by penetration, and the borehole was eventually successfully sunk to a depth of 99 feet, yielding an abundant supply of pure water.

The project was so important that it attracted the attention of The Engineer, a leading technical publication devoted to advances in the profession. Their issue of June 22nd described in detail the latest development and the account illustrates the complexity of the operation:

ARTESIAN TUBE WELL

At the waterworks of Bourne, Lincolnshire, a remarkable spring, rising 7ft. above the surface, has been tapped in the "oolite" formation, at the depth of 120ft. from the surface, yielding at the rate of 36,000 gallons per hour. The work was carried out through the strata. At a depth of 25ft. impure surface water was obtained and the annular [ring-shaped] space between the 10in. and 5in. tubes was filled in with cement. The 10in. wrought iron tube shod with a steel end is carried down to a depth of 43ft., where it is tightly embedded in the rock, so as to exclude all surface water. From this depth, a 5in. boring is continued to a depth of 120ft. and lined to a depth of 88ft. with wrought iron lap-welded tube with steel sockets and shoe. Special precautions had to be taken during the progress of this well to prevent the springs from finding their way outside the pipes, as is the case with most of the wells in the district. In this instance, wrought iron lap-welded steel socketted tubes of extra thickness were fixed down to the first bed of rock, these being tightly driven with an 8cwt. monkey the whole of the distance. From this point, 5in. tubes were inserted to a depth of 88ft. from the surface. During the operations, two springs of a chalybeate nature were met, these being effectually excluded by the driving of the pipes into the lower strata. The water-bearing rock was reached 88ft. from the surface, the water from which overflowed at a very slow speed as soon as it was met with. On the depth of 99ft. from the surface being reached, the flow of water was found to be 12,000 gallons per hour and it was decided to try the experiment from the bottom of a borehole that existed in the town 88ft. deep and 2in. internal diameter, but owing to the breaking of a boring tool in the hole some 25 years ago, it had been abandoned after fruitless attempts to recover it at the time. The broken tool was recovered with a very simple contrivance after three days' work. The boring proceeded and it was found that the further the rock was pierced, the stronger the yield, so much so, that at the depth of 120ft. the supply was so satisfactory that it then decided to deepen the first-mentioned bore. The work was then continued at this bore by the contractors, Messrs C Isler and Co., London, with the result that at the same depth, the yield was threefold that obtained at 99ft., viz 30,000 gallons per hour.

Two important boreholes were sunk in Bourne during 1891. The first, in March, was completed by Messrs Eldred to supply the new brick works that had been opened near Stamford Hill to supply the Midland Railway Company. The contractors found a plentiful supply at 81 ft. 9 in., the average depth of borings in Bourne at that time being 95 ft.

In

the same year, Messrs Thomas Nowell of Bourne were instructed by the Midland Railway

Company to sink a borehole to supply the new railway station, a short

distance from the Red Hall. The work was completed in April with a bore of

2½ in. in diameter and a depth of 85 feet. A report on the project said:

"The quality of the water is excellent and although the bore is

small, the quantity is amply sufficient to supply the whole of Bourne. The

geological data of the soils penetrated vary slightly from those already

known. About 13 ft. of red sandstone overlies the subterranean stream in

this spot. The first 7 ft. of this rock is very hard but as the water was

approached, the rock became more pervious and was easily penetrated. One

peculiar feature deserves special notice. A bed of white clay, highly

prized in the ceramic art for its purity, being the kind utilised for the

finest description of pottery, occurred at a depth of 72 ft. The bed,

however, was not more than 2 ft. in thickness."

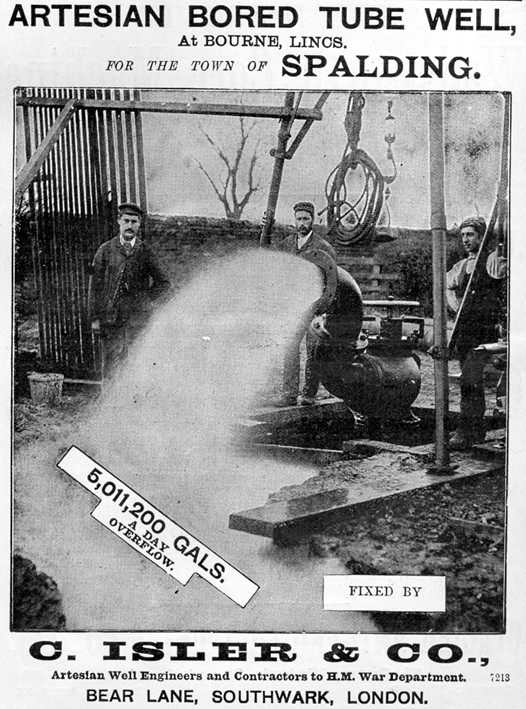

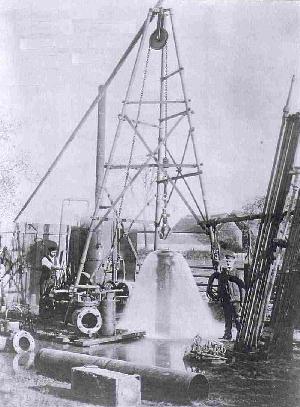

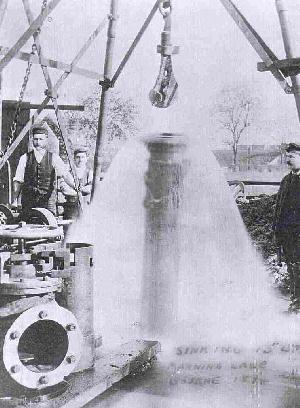

Another important borehole was sunk for the Bourne Waterworks Company in Abbey Road, supplying not only the town but also Spalding 13 miles away, with five million gallons a day. The Stamford Mercury reported on Friday 2nd February 1894: A remarkable overflowing artesian well has been recently sunk at Bourne to supply the town of Spalding with water, the engineers being Messrs C Isler and Co of London. It is stated that no records are published of springs being tapped in England yielding a larger quantity of water than the one at Bourne. At a depth of 100ft. from the surface, the yield was 1,872,000 gallons per day; and on the advice of Messrs Isler, it was resolved to carry the bore deeper with the result that at 134ft., over 5,000,000 gallons per day are now obtained. The overflow really proved wonderful and unless means had been taken for carrying this water away into a dyke which runs into two rivers, the country around would have been flooded. The water from the well flows by gravitation through ten miles of pipes to the company's reservoirs at Spalding.

Another local company engaged on this work was Messrs Thomas Gelsthorpe and Sons, builders and contractors, of North Road, Bourne, who completed a successful drilling on Mr Thomas Carlton's property in Gladstone Street in 1896. A bed of compact limestone was found at 50 feet and then a stratum of bluish clay only 1½ inches thick. Water bearing rock was found 150 feet below the surface and the three-inch bore eventually yielded sufficient supplies for the entire town.

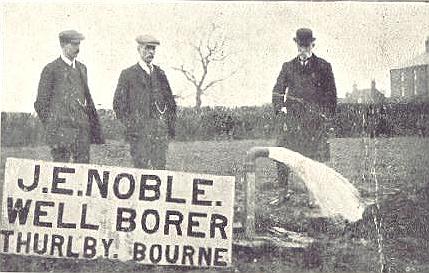

The rural area was also getting its share of boreholes such as the one completed at Baston Fen in the summer of 1897 on land owned by Lord Kesteven. The Stamford Mercury reported on Friday 2nd July that "the water rock was tapped at a depth of 170 feet when a very fine supply of water was obtained, rising 20 feet above the ground and yielding an overflow of 5,000 gallons per hour. The people round are fetching it for drinking purposes, as a spring of pure water in the fen country is a thing to be talked about but not often realised. Mr Noble of Thiurlby was the contractor for the work. Tanks are fixed in the crew yards which always stand full, being fed from the bore, which, no doubt, the tenant, Mr G Peasgood, fully appreciates." Then in the autumn of 1905, a borehole was sunk on the estate of William Castledine at Tongue End. The Stamford Mercury reported on Friday 3rd November: The first spring was tapped at 196 feet. A succession of springs was then tapped up to 219 feet when the overflow was 4,000 gallons per hour. The boring is tubed to water and sealed so that there is no escape and there is sufficient pressure to lift the water 30 feet above ground level. Mr Noble, of Thurlby, had the work in hand. The wells now being sunk were becoming more prolific as the years progressed and one of the most successful operations was carried out in the autumn of 1906 on the estate of Mr Thomas Mills in Abbey Road. The Stamford Mercury reported on Friday 30th November: The boring was continued to a depth of 98 feet when the water gushed up, sending a column four feet above ground level. The pressure was so strong that it was with the greatest difficulty the tubes could be got in and sealed, the men being drenched to the skin. The boring gives an overflow of 905,000 gallons per 24 hours. This is the largest supply of water ever tapped in Bourne from a 4½ in. bore. Mr Noble, of Thurlby, near Bourne, who is well known for this class of work, had the job in hand.

By 1969, there were an estimated 130 artesian bores within the urban district of Bourne, supplying farms, factories and housing developments. However, all water in the Bourne area is now drawn out through boreholes administered by Anglian Water which supplies a much larger catchment area, often to the disadvantage of the town because both St Peter's Pool and the Bourne Eau have been known to dry up during spells of drought in recent years. Boring for new wells needed an expert and there were several of them in the Bourne area. John Elwes Noble of Thurlby was one of the better known and he carried our drillings for many local authorities and industrial firms. His son also worked in the business which was later known as John Elwes Noble & Son, and they sent details of the strata and location of every bore they drilled to the Geological Society in London which assisted them in their compilation of the geological survey of England and Wales.

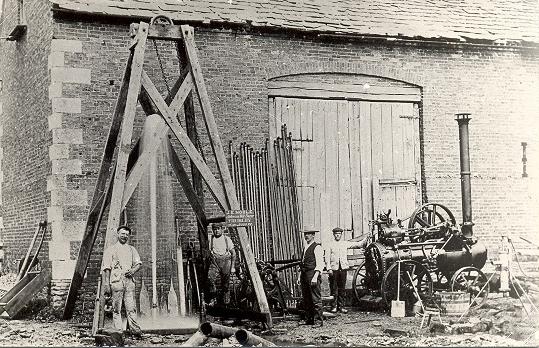

The picture above comes from one of his trade cards which shows him at work for Bourne Rural District Council about 1900 with a similar operation underway from the same period below while the bottom picture shows John Noble junior and his staff at work on a borehole for Thurlby Manor in 1940. Other clients included district and parish councils, Bourne waterworks and companies at Horbling, Baston, Market Deeping, Greatford and Morton. As well as being an artesian well borer, John Elwes Noble also had a reputation as a water diviner and advertised his professional services as a blacksmith, builder, cabinet maker and carpenter, funeral director, glazier, painter and decorator and wheelwright and in addition he sold lamp chimneys, machine oil and sand, and also worked as an assistant overseer or the poor, rate collector and church organist.

Noble was responsible for sinking bores at Dowsby Hall, West Deeping vicarage, Bourne Workhouse and for William Wherry and Thomas Mays of Bourne and R A Gardner, the magistrate and artist who lived at Cawthorpe Hall. In January 1898, he sank the Morton bore in Haconby Lane where he tapped water at a depth of 106 feet and had an initial flow of water of 6,000 gallons an hour. The strata he passed through in descending order were sand (7ft.), clay (4ft.), rock (9ft.), clay (19ft. 9in.), rock (10ft. 2in.), clay (9½ft.), rock (3ft.), clay (18½ft.) and rock (27ft.) The flow of water was so prolific that there was sufficient to supply farms and dwelling houses in the east end of Morton village.

Return to Water supplies See also The origins of Bourne The aerated water industry The sewage

system Water cress and

chysanthemums Marjorie

Noble MBE

Go to: Main Index |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||