|

The brewing industry

The first people in Bourne to produce beer

in any quantity would have been the monks at Bourne Abbey. Later, large

houses or mansions, such as the Red Hall, had their own brewhouse for the

production and storage of ale and beer.

A commercial brewery existed in North Street, Bourne, in the early 19th

century owned by John Davidson but he got into financial difficulties and

was forced to sell up. The business

was taken over in 1841 by Messrs Thomas Lawrance and William Daniell who inserted

a public notice in the Stamford Mercury on Friday 12th February

seeking the continued support of customers. "The proprietors have pleasure

in assuring the public that their object will be to supply such a genuine

and wholesome beverage as will induce their friends from motives of

economy and comfort to forego the annoyance and disappointment so

frequently arising from brewing at home. Indeed, they are anxious that

their establishment should become the great desideratum of a private as

well as that of a public brewery."

They began trading as the North Street Brewery, proprietors Lawrance and

Daniell, but the partnership foundered and was dissolved in June 1843

leaving Lawrance to run the business on his own. Then in 1845, he sold out

to Mr W B Edwards, a brewer, from Stamford. Other smaller breweries also

operated in Bourne at that time such as that run by Charles Spreckley in

Eastgate and at the rear of the Angel Hotel run by the landlord Henry Bott

although many other public houses also brewed their own beer for sale on

the premises.

Later in the century, Robert James Shilcock

opened the Star Brewery in Manning Road and this was the largest

undertaking of its kind in the town.

In 1884, it was taken over by Joseph Wyles and in

1891, it became a limited company under the title of Joseph Wyles and Co

(Bourne Brewery) Limited with a share capital of £20,000. The Stamford

Mercury reported:

From enterprising management, rapid development,

and the increasing trade of the firm, there is little doubt that the shares

will be quickly subscribed and that the new departure will lead to still

further development and prosperity. It is acknowledged by competent

authorities that Bourne water is excellently adapted for brewing purposes and

there is no reason why Bourne should not become one of the most important

centres of the brewing industry in the country.

The number of barrels of beer being sold at

this time was 3,500.

The business became Bourne Brewery Ltd in 1898

and in 1913 it was taken over by Charles Campbell MacLeod and subsequently by

Soames and Co Ltd in 1922. Brewing ceased in 1937 by which time the premises

were described as "a beer depot".

The last of the brewery buildings disappeared in 1965 to make way for the premises of

Johnson Bros (Bourne) Ltd, the agricultural machinery engineers, but the

company vacated the site in 2005 and it is now occupied by the Browning Court

retirement homes development.

|

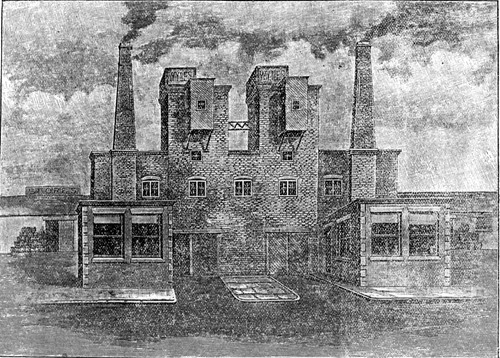

A TOUR OF THE NEW BREWERY |

|

TO THE TRAVELLER in the

fertile district of Wold and Fen, immortalised by the early exploits

of the Saxon hero “Hereward the Wake”, one of the most striking

architectural features is the new brewery of Messrs Joseph Wyles &

Co., through whose spirited enterprise Bourne bids fair to out-rival

far larger and more pretentious towns engaged in the manufacture of

our nation beverage. “Wyles’s Bourne Ales” is rapidly becoming a

household word among lovers of a “glass of good beer”.

One tower of the new building is already erected, and the other is

approaching completion. The rapid and increasing development of the

business has been remarkable, and affords a striking example of the

results of genuine enterprise and industry.

Six years ago, Messrs Wyles took over the business from Messrs

Shilcock & Son. Seeing the exceptional advantages possessed by

Bourne, in its unfailing supply of the purest water in the world,

for the establishment of a splendid brewing trade, the firm

determined to spare neither energy nor capital in utilising to the

utmost the natural advantages. Their enterprise has been completely

justified by the results. From the commencement their output has

been continually increasing.

Additions and alterations were being constantly made to the

buildings which proved totally inadequate to the increasing demand;

and in 1889 the business had so largely developed as to render

absolutely necessary the erection of considerably enlarged premises.

The original building has therefore been superseded by the present

palatial structure, with more than ten times the accommodation.

In the course of an interview with Mr Joseph Wyles, we enquired to

what he attributed this rapid development. “First and foremost”, he

replied, “to the unequalled excellence of the Bourne water, which is

second to none in England for brewing purposes; and, what is equally

important, to the fact that from the commencement we have made a

point of guaranteeing to our customers absolutely pure beer, brewed

only from English hops and malt.”

We granted by reputation Bourne water was the purest in England, but

requested Mr Wyles to inform us what authentic scientific evidence

there existed in support of this statement. He at once produced such

a formidable array of scientific authority in proof that scepticism

was impossible. Analysts like Professor Tidy and Dr. Lankester,

whose reputation is world wide, and the country analyst, Dr. Lowe,

as well as no less an authority that Granville Sharpe, bore

unanimous testimony that their analyses of Bourne water demonstrated

its absolute purity. “It is unrivalled for brewing purposes.”

Geologists have calculated that the volume of pure spring water

flowing under Bourne is equal to that of the Thames.

We have already alluded to the rapid and increasing development of

Messrs Joseph Whyles & Co’s business. The trade of the firm has

doubled since last May, and there appears every reason, from the

present rate of progress, to anticipate that this production will be

doubled by next year. Branch establishments have been opened at

Grantham, Boston and Peterborough. According to the recently issued

official Excise returns, Messrs Joseph Wyles & Co’s business showed

the largest increase of trade on the year of any other brewing firm

in the county of Lincoln.

The new building is both conspicuous and imposing. The height of the

tower is 50 feet and the summit commends a splendid prospect of the

surrounding country. The building is in brick, with stone facings.

It is commodious and substantial, and is throughout a model of

cleanliness and order. The whole of the machinery and appliances are

of the most approved modern type, the latest improvements in brewing

operations being fully utilised. The top floor or lofty tower is the

malt and milling room, with malt and grist cases and malt mill. On

the summit stands the cold liquor vat, capable of holding sixty

barrels (2,160 gallons). The sides of this area adorned with the

name “Wyles”, in letters so large that he who runs may read. The

roof is of lead and the coping of stone.

Descending the ladder from the milling room, we enter the mash-tun

room, with mashing machinery, hot liquor tank, and a vertical steam

engine of 10 hp. Sorrell's patent mashing machinery is employed. To

the hot liquor tanks are attached glass gauges, indicating

temperature and quantity. Below this comes the copper stage. The

copper for boiling worts has a cubic capacity of 1,460 gallons. This

room comprises the liquor and wort pumps. One of the wooden wort

coolers on this floor holds 762 gallons. After viewing the large

copper furnace, we inspect the compartment below this, which is

known as the round room, the most conspicuous object in it being a

thirty-barrel refrigerator (Laurance’s patent). One of the details

in this stage that deserves notice is Sorrell’s patent mop cleaner.

As the thorough cleanliness of the mops employed in the numerous

processes is very essential, this efficacious but unpretentious

contrivance has an important function in the brewing economy.

On the same stage is located the fermenting room. There are five

fermenting vessels, rounds and squares, each of 40 barrels (1,500

gallons) capacity. Perhaps in this delicate department of the

manufacture, almost more than any other, personal experience, close

observation, scientific knowledge, and mechanical ingenuity are

required.

Messrs Wyles have spared no pains to secure these essentials. We

noticed that the fermenting vessels are supplied with fixed

attemperators and parachutes. In the square room are two square

fermenting vessels, with attemperators and parachutes. Descending

another flight of steps, we wind our way through rods and wheels and

intricate machinery (duly guarded) to the laboratory, where all the

beers are submitted to a searching chemical analysis, and all the

materials employed in the process of brewing are thorough tested by

Mr A Sorrell, a qualified analyst, and a late pupil of Professor

Graham of University College, London.

The array of scientific apparatus, chemical balances, microscopes,

test tubes, reagents, compactly ranged round the room, impart to it

quite a learned air. An accurate acquaintance with chemical

researches, and a practical knowledge of laboratory practice, are

now indispensable adjuncts of successful brewing.

The Bourne firm are fortunate in securing the services of so able

and analyst as Mr A Sorrell. Passing through the hop room, and

taking our final flight, we land on the ground floor, where we find

ourselves set in the midst of tiers of barrels. Here are the beer

stores and racking and cleansing rooms. We observe the carters

replenishing their conveyances, to bear off the manufactured

articles north, south, east and west. On the ground floor is the

boiler house. The boiler is of fourteen horse power, and is supplied

with a horizontal pumping engine. The cart-sheds are located in the

yard, as are also the patent cask steamers.

The entire plant is arranged for Mr Sorrell’s system of brewing.

This gentleman is an expert in the art, his experience extending

upwards of forty years. Mr Sorrell conducted us through the various

departments, and proved a most genial, as well as instructive guide.

The engine work in the establishment has been supplied by Mr Arnold

Pick, Bourn, the copper work by Messrs Bennett & Co., London, and

the wood work by Messrs D Roberts, Tottenham. Messrs Chappell and

Wall, of Bourne, were entrusted with the building, and Mr William

Harrison with the plumbing work. The view of the brewery was

sketched by Messrs Glendenning, Bros., Bourne.

NOTE: This

article is reproduced from the Lincolnshire Free Press, 29th July 1890,

together

with the picture (top) showing the brewery in Manning Road

from a drawing

by the Glendening brothers who lived at the Red Hall. |

|

FROM THE ARCHIVES |

|

John Cawkwell Farrow Davidson, of Bourne, brewer

and maltster, appeared before the Insolvent Court at Lincoln on Thursday

4th August 1842. The insolvent, a young man, very early in life, was

started in business and had a good fortune from his grandfather but

improvident habits compelled him to borrow largely of relatives and

friends; their demands were stated at £4,987 18s 1d, and he had assigned

to them £4,561 13s. 8d.: the remainder of the debts from which he sought

relief was only £300. The court said the friends ought to pay that

trifle; and, to give them an opportunity of doing so, it was ordered

that the insolvent should be imprisoned for six months. - news report

from the Stamford Mercury, Friday 12th August 1842.

Letter to the editor - Sir: As a lover of peace and quietness, I

consider it my duty to protest against the unearthly shrieking “buzzer”

which, from six o’clock in the morning until the same hour at night, at

regular recurring intervals, disturbs our repose. With all respect to

the spirit of enterprise which has prompted its introduction, could not

some gentler sound be contrived, by means of which all whom it concerned

might be apprised of the solemn fact that it is time to commence or

cease their labours? I have not yet made any experiments as to the range

of distance over which the terrible “buzzer’s” yell traverses, but it

must be indeed a considerable area. It certainly serves to keep Messrs

Joseph Wyles and Company’s enterprise, if not well before the eyes of

the public, any way continually in their ears. Sir, there is no escape

from its scream! Ah! There it goes again! Like Brutus in his eloquent

oration, “I pray thee give me pause” until it is done. I am not required

at my occupation at as early an hour as six o’clock in the morning; and

Bourne has hitherto been so quiet and un-Birmingham-like in all its ways

(saving only politics), that I thought I should never be aroused from my

sweet morning sleep before the usual time. Alas and alas! I am compelled

to wake at six! That buzzer is enough to wake the nation. And its sound

haunts me now! As plainly as the voice of accusing conscience to the

guilty Macbeth, it cries “Sleep no more!” The buzzer “doth murder

sleep”.

I thank you in anticipation for inserting this. I don’t suppose it will

have the least practical effect. Businessmen have no sentiment and their

organs of hearing must be tough as well. But it is a relief to ease

one’s feelings! I suppose we cannot stop the onward march of progress,

and buzzers are its herald. I may say that most of my bachelor friends

feel this matter as keenly as I do. Married men make no complaints:

their spirits are subdued, I suppose. Moreover, their “olive branches”

are even more effectual rousers than buzzers! At least, so thinks one

who is perforce now AN EARLY RISER.

– published by the Grantham Journal, Friday 3rd May 1890. |

See also

The Old Maltings

A case of contaminated water

Go to:

Main Index Villages

Index

|