|

Water power produces

green electricity

MAJOR RESTORATION PROJECT AT

THE MILL

|

This is a fantastic achievement. You don't see

water wheels built every day of the week.

- quote by Mrs Brenda Jones, chairman of

Bourne Civic Society, 30th May 2008. |

A REMARKABLE environmental achievement came to fruition

in May 2008 with the opening of the newly restored water wheel at

Baldock’s Mill in South Street, Bourne.

The experiment in producing green energy was the brainchild of Jim Jones,

aged 68, a retired engineer and active member of the Civic Society who was

responsible for the design, construction and installation as part of a

project which originally began in September 2002 with the building of a

wooden replica of the original wheel. But once this was up and running as

a visitor attraction, he decided on a more ambitious scheme by

constructing a durable, metal waterwheel with a practical purpose. Design

work began in September 2007 and after eight months of hard work, the

wheel began generating electricity to offset the rising cost of heating

and lighting the building which is home to the town’s Heritage Centre.

There has been a watermill on this site since the Domesday Book of 1086

but the present building dates back to 1800 and for well over a century

was powered by the fast flowing waters of the Bourne Eau to grind corn and

taking its name from the last family to work it, i e Baldock. The mill

wheel was 15 ft in diameter by 3 ft wide and there was a smaller fly wheel

measuring 5 ft by 1 ft. Corn was brought in to be ground into animal feed

by farmers and smallholders who paid for the grinding. Maize was also

split for chicken feed and horse beans and a flour dresser provided

sufficient for the family's own use.

Two sets of stones operated on the first floor fed from hoppers on the

floor above, the corn being lifted up from the ground floor where it had

been previously delivered by a chain hoist driven, like the stones, by the

wooden undershot water wheel. Access to the two upper floors by the miller

was by ladders. The mill operated twice a day for three hours and this

time was increased by the digging of the leg of the river between the

paddock that is now the War Memorial Gardens and the Wellhead cottage.

After powering Baldock's Mill, the water then ran downstream and could be

used by Notley's Mill in Eastgate which was demolished in 1970.

A gas engine was run at other times to provide power and as the owner, Mr

Frederick Baldock, ran a carpentry and timber business from the premises,

it also kept his saw bench in operation. Ground meal was packed on the

downstairs floor, using the same bags brought in by the farmers, then

hoisted up to the store on the first floor ready for collection via a

wooden chute that was attached to the iron bar that can still be seen

today below the stable door entrance. The mill stopped working about 1924

when the water wheel collapsed and the owner, the Marquess of Exeter,

called in experts to inspect the damage but decided not to repair it

because of the high costs involved.

The mill has had several uses since then and in 1977 it was listed Grade

II as being of architectural and historic interest and in 1981, Bourne

Civic Society sought permission to turn it into a Heritage Centre and

Bourne United Charities agreed to lease them the building for a peppercorn

rent in order that it would be preserved for community use. The agreement

was renewed in 2002 for a further 21 years and the full potential of the

building in this new role is slowly being realised.

When the mill ceased production, the water wheel and machinery were

removed but the mill race remained, the narrow concrete channel beneath

the building which harnesses the river flow controlled by a small sluice

gate, and it is here that the new wheel is being installed to produce

electricity. Jim and dedicated helper, Doug Fownes, aged 66, a retired

production engineer, have spent more than 400 hours on the installation

using equipment and parts made locally. Technical advice has been

forthcoming from the Pedley Wheel Trust at Adlington, near Macclesfield in

Cheshire, which has its own home made overshot waterwheel generating

domestic electricity while the Rotary Club of Bourne promised financial

backing for the £6,000 project.

The new wheel is 11.5 feet (3.5 metres) in diameter and fitted with forty

steel paddles coated with red oxide paint while the spokes are made from

water resistant iroko, a light coloured hardwood from Africa that had been

chosen for the project for its strength and durability and all of the

sections had been specially varnished to repel moisture. A £2,000 gearbox

and generator have been connected to capture the energy from the wheel and

when working at full capacity, it gives 140 revolutions per minute driving

the 1.5 kW generator, thus producing 36 kilowatt hours (kWh) every day and

13,140 kWh each year, firstly to power the lights in the mill and later as

an input into the national grid for a financial return at a variable rate

of between 10p and 15p per kWh, so reducing the annual electricity

bills.

The official opening was held at noon on Saturday 24th May 2008 when the

project was declared open by Canon David Staples, president of the Rotary

Club of Bourne, and attended by more than 70 guests. He is pictured below

(right) with Jim and Brenda Jones (front) and Gerry Colyer of the Rotary

Ckub.

|

PHOTO GALLERY OF WORK IN PROGRESS |

|

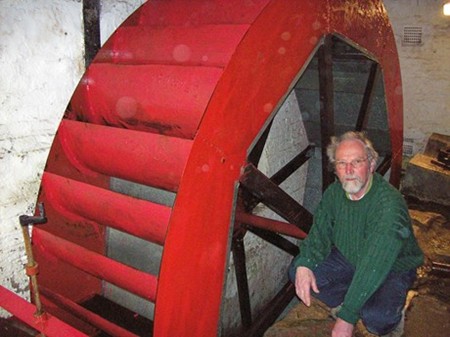

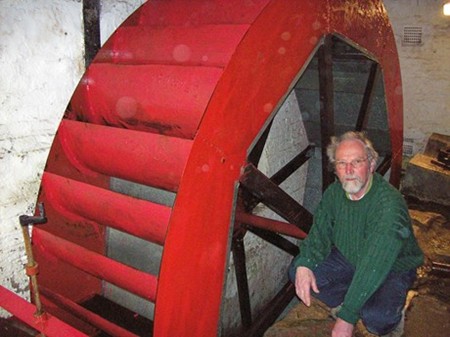

Busy within the mill race area in February 2008 with

Jim Jones (front) and his willing helper, Doug Fownes, and fitting the

generator (below). |

|

|

|

|

|

|

AWARDS FOR THE WATER WHEEL PROJECT |

|

|

|

|

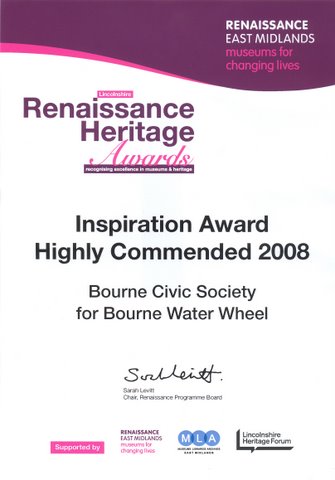

The Water Wheel Restoration Project won two

awards during the summer of 2008 and the certificates now hang in

the Heritage Centre. The first was a Highly Commended

Inspiration Award from Renaissance Heritage Lincolnshire and the

second for taking top place in the environment and culture category

in the East Midlands Market Town Awards. |

Go to:

Main Index Villages

Index

|